- Thu 07 February 2019

- articles

- Norcimo

- #3D printing, #model

The university library only allows drinking from bottles with a screw cap or from "completely sealed cups" inside the library area. I usually drink cans, and I prefer to drink them while studying instead of going to the vending machine area and drinking them in one go.

Most students just ignore this rule and they take their cans inside anyway, but I felt like I could tackle this problem in a better way.

First attempts

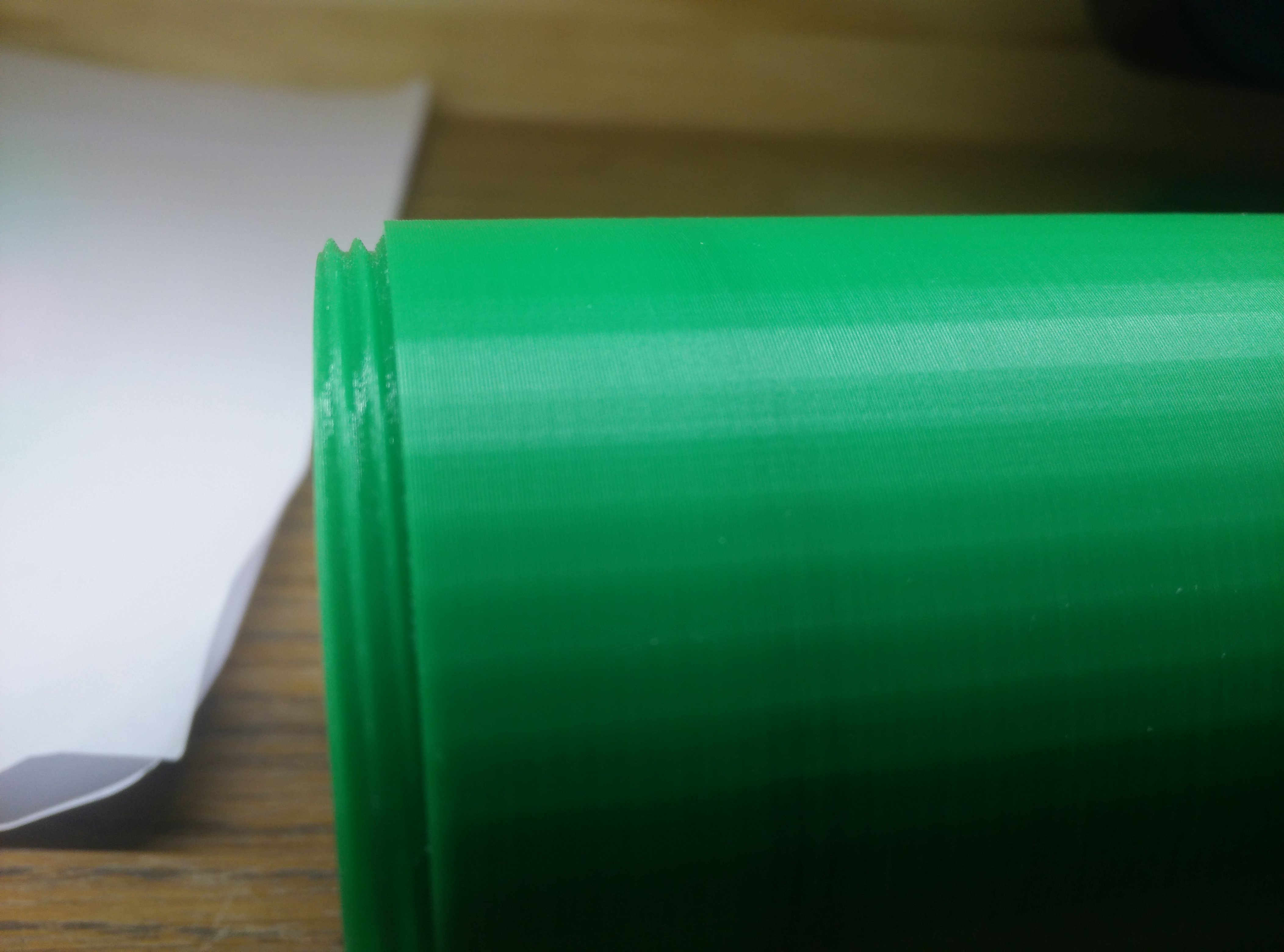

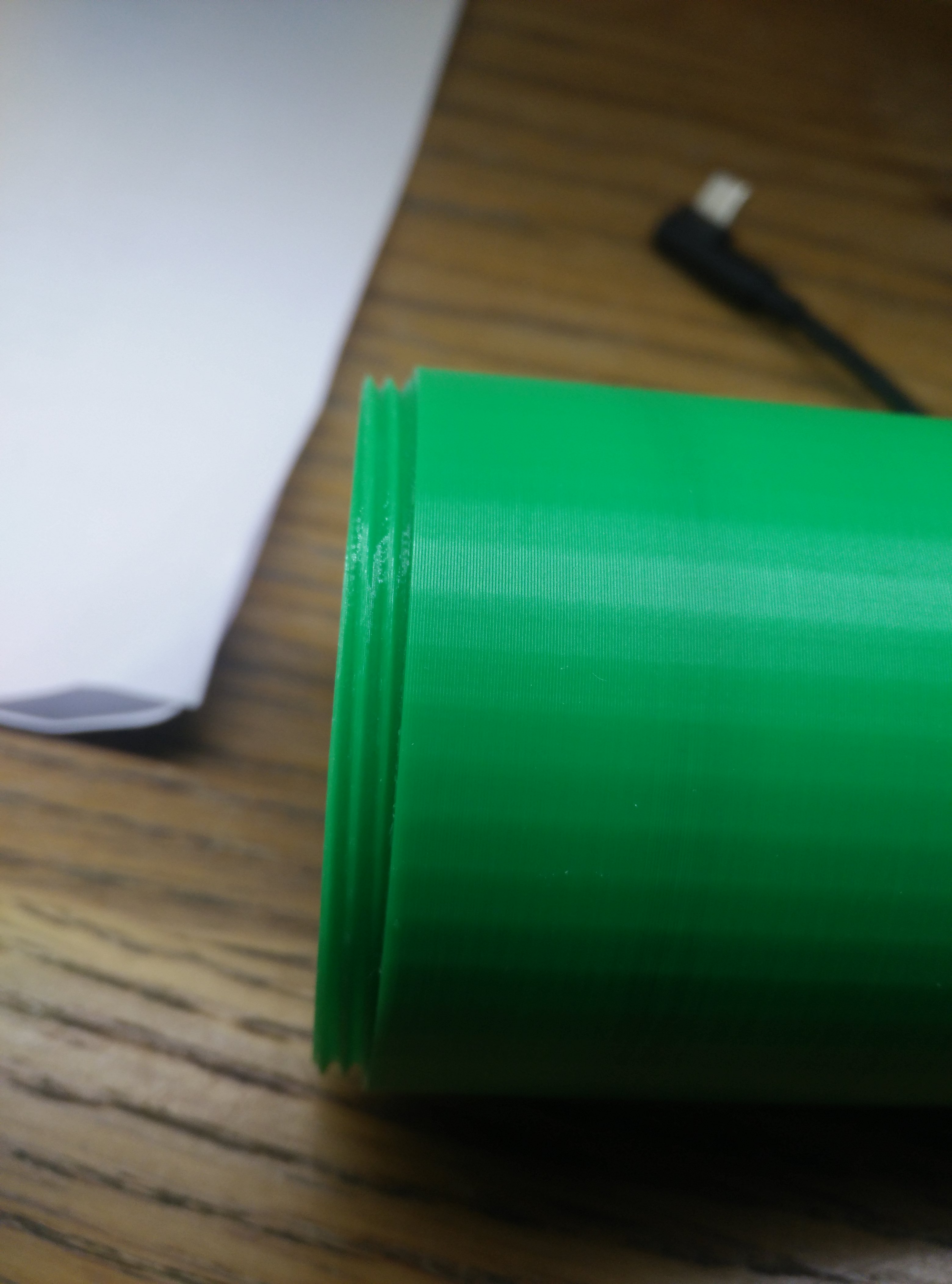

Initially I wanted to create a clip-on cap that would seal the can, but this quickly proved to be complicated. The clip was either too loose and didn't provide proper sealing or it was nearly impossible to remove. I went through several clip-on iterations before I decided to create a full can holder instead.

The first can holder I designed worked more or less but had a "slight" annonyance:

It takes about 7 turns to unscrew the cap. Having to do that every time you want to take a sip is way too annoying. Ideally you want to be able to unscrew the cap in a single movement, about 1 turn of the cap. It's not feasible to achieve that by only reducing the length of the thread because then the cap will barely hold on to the body of the holder.

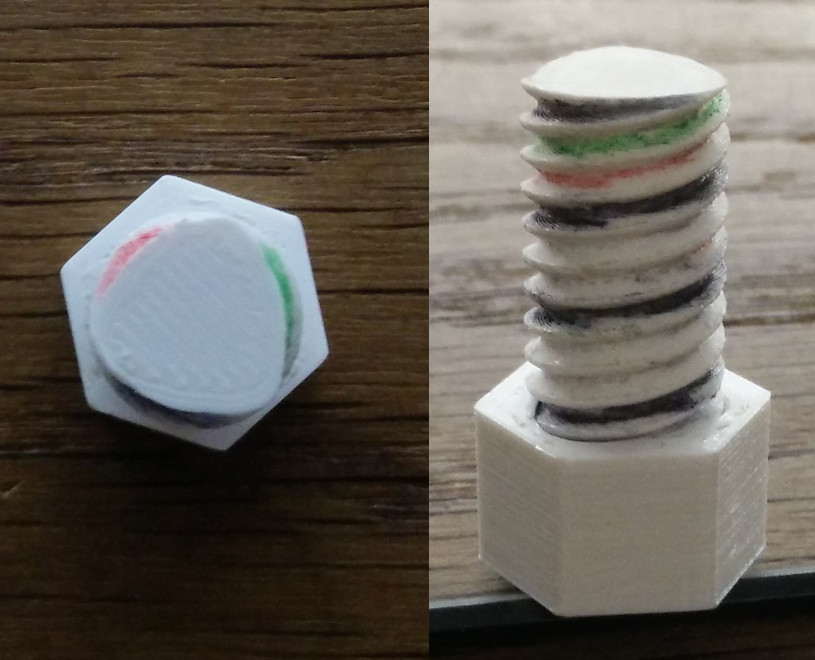

Multi-start threads

To solve that issue I used a multi-start thread. The advantage of a multi-start thread is that it covers more distance in a single turn. If your thread has 3 starts it will cover 3 times as much distance in a single turn as a thread with a single start.

The disadvantage is that all starts of a multi-start thread must be engaged at the same time to properly screw on the cap. This isn't so much of an issue here because the can will guide the cap in place making it correctly fit onto the body automatically.

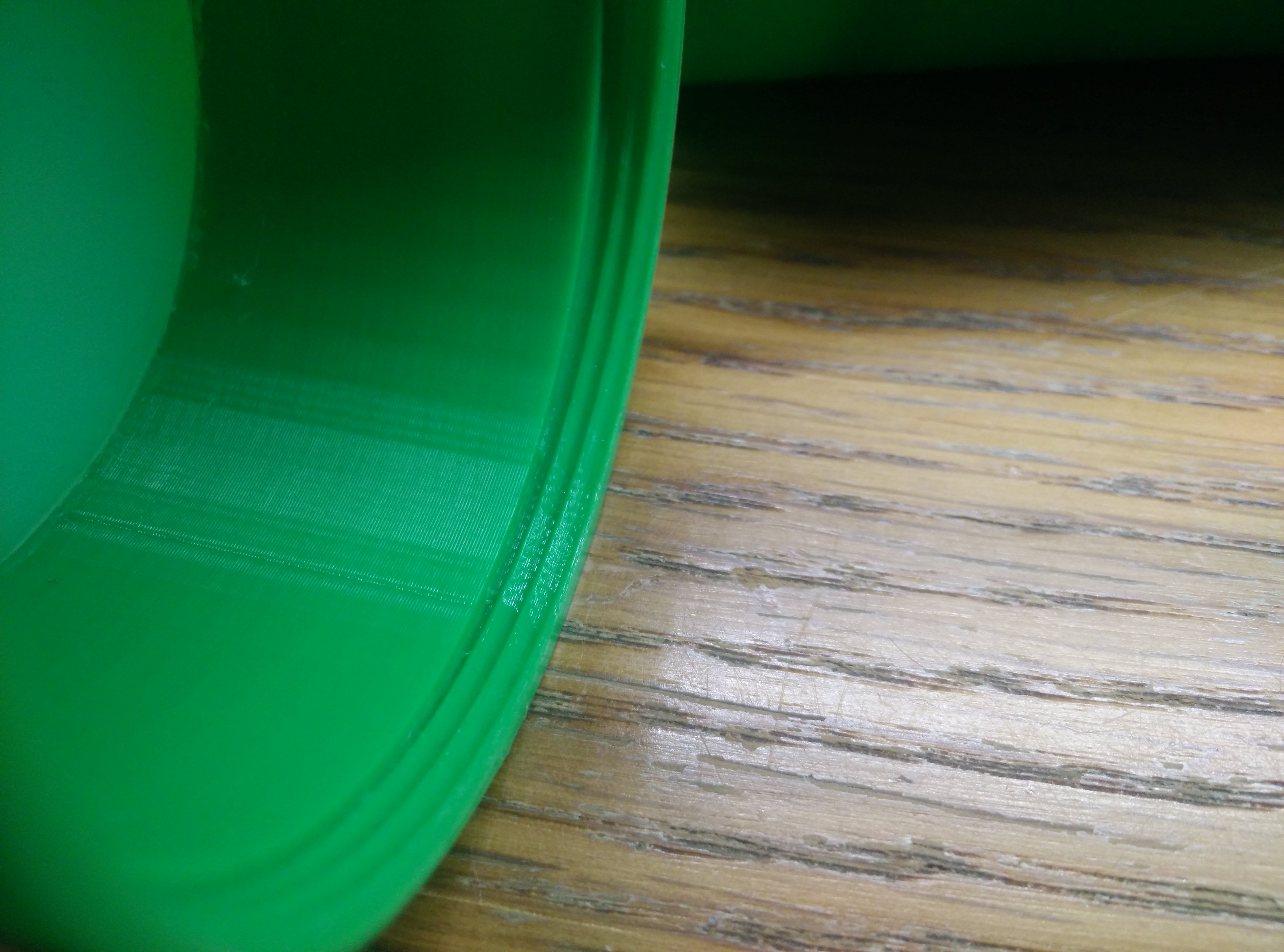

Silicone pad

A final issue was that the cap didn't provide a proper seal of the can. I solved this by ordering some food safe two-part silicone online and creating a small silicone pad to place into the cap. This forms a proper seal that can withstand the pressure of the carbonated soda even when vigorously shaking the closed can holder.

Since the silicone pad is the only thing that comes into contact with the beverage I also don't need to worry about potential bacteria buildup in the layers of the printed PLA. On top of that it's removable, so I can wash it off in case I would forget it in my bag over the holiday so that mouth and skin bacteria combined with left over liquid could run rampant all over it. Not that that has ever happened before.

Files and printing guidelines

I've printed this on a Prusa MK3 with a .4 mm nozzle using PLA from das filament. The model was sliced with Slic3r PE using a .2 mm layer height for most of the model except for the thread, which was sliced at .1 mm layer height.

The models and the FreeCAD project file are available for download and are licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Included in the archive you find can_holder.FCStd, this is the (mostly)

parametric FreeCAD project file. There are also three model files

(can_top_final.amf, can_bottom_final.amf, silicone_mold.amf) already

exported from the FreeCAD project and ready to be sliced. I taped the mold down

onto a flat surface to pour the silicone pad, but you can probably also pour

silicone directly into the cap instead. The pad might not be removable in that

case.

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

The final product

The final product provides a proper seal, opens in a single turn and abides by all the library regulations.